Pulsafeeder® The Complete Manufacture Solutions for the Oil and Gas Industry

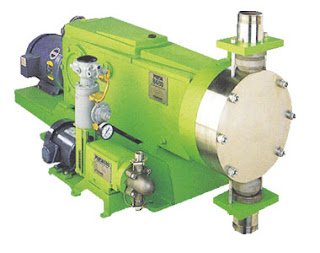

Pulsafeeder® The Complete Manufacture Solutions for the Oil and Gas Industry Pulsafeeder ® offers solutions for the oil and gas industry, ensuring operations and safety through precise fluid handling. Metering pumps , also known as dosing pumps or hydraulic diaphragm metering pumps , play a role in injecting chemicals throughout all stages of the oil & gas industry. These include: Production Processing, and Transportation This article explores Pulsafeeder's range of metering pump solutions tailored to meet the requirements of the oil and gas sector. The Significance of Metering Pumps in Oil and Gas Metering pumps are essential in oil and gas applications. In injection processes, they are crucial for dispensing specialised chemicals like corrosion inhibitors, scale inhibitors, and demulsifiers at strategic points during production. This precision is key to preventing equipment corrosion, optimising flow efficiency, and ensuring product separation. Additionally, metering p