Gear Pumps Selection Guide: Types, Features, Applications

|

Gear Pumps Selection Guide: Types, Features, Applications

Gear pumps have earned a reputation for their efficiency and

reliability, characteristics that stem from distinctive features inherent to

their design. Notable among gear pumps features is their simplicity with a few

moving parts, making them highly reliable and easy to maintain. The design of

gear pumps facilitates the efficient handling of viscous fluids, showcasing

their high efficiency. These pumps possess the valuable capability of

self-priming, eliminating the need for an external suction source to initiate

pumping. Their versatility is evident in their ability to manage a broad

spectrum of fluid viscosities and pressures, rendering them suitable for a

diverse range of applications. Renowned for their durability, gear pumps are

constructed robustly, ensuring a long service life. These collective gear pumps features position

them as a preferred choice across various industries. The optimal selection of

a gear pump necessitates a comprehensive understanding of its operational

nuances, the available types of gear pumps, and the specific requirements of

the intended application.

How do I choose a gear pump?

Selecting the appropriate gear pump for your application is a

nuanced process that involves careful consideration of various factors. To

embark on this decision-making journey, the initial step is to gain a profound

understanding of your application's requirements. Questions about the type of

fluid the pump will handle, the viscosity of the fluid, and the desired flow

rate and pressure are integral in this regard. Following this, the choice

between external gear pumps, suitable for high-speed applications, and internal

gear pumps, ideal for handling high-viscosity fluids, needs to be made. Material

compatibility is crucial, necessitating consideration of construction materials

that align with the properties of the pumped fluid, especially in cases

involving corrosive or abrasive substances where more durable materials like

stainless steel may be required. Thoroughly checking the pump's specifications,

including capacity, pressure rating, speed, and power requirements, is crucial

to ensuring alignment with application needs. Assessing the reputation of the

pump manufacturer becomes a vital step, favoring those recognized for quality,

reliability, and robust after-sales service. It is imperative to invest the

necessary time and effort into making an informed decision, as the right gear

pump holds the potential to significantly enhance operational efficiency and

reliability.

What are the 2 types of gear pump?

Gear pumps are broadly classified into two types: External Gear

Pumps and Internal Gear Pumps. Let's delve into each one:

·

External Gear Pumps: These are the most common

type of gear pumps, consisting of two identical, interlocking gears. The

driving gear is connected to the drive motor, which turns the driven gear. As

the gears rotate, they create a void on the inlet side, which creates suction,

and the fluid is drawn into the pump. The fluid is then carried around the gear

teeth to the outlet side, where the meshing of the gears displaces the fluid.

·

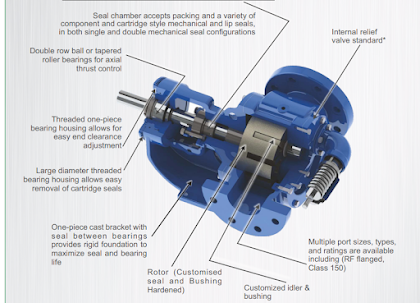

Internal Gear Pumps: These pumps consist of a

gear within a gear. The outer gear (usually a rotor) has one tooth more than

the inner gear (usually an idler). The fluid is drawn into the pump at the

point where the gears come out of the mesh and is carried to the outlet in the

space between the teeth and the casing. The fluid is then forced out of the

pump as the gears mesh together.

Each type has its own advantages and is suited to certain

types of applications. External gear pumps are typically used for tasks

requiring high speeds, while internal gear pumps are better suited for handling

high-viscosity fluids.

How do internal gear pumps work?

Now, let's dive into the working mechanisms of both types of

gear pumps.

·

External Gear Pumps: In an external gear pump,

two identical gears rotate against each other. One gear is driven by the motor

(drive gear), which in turn drives the other gear (driven gear). When these

gears rotate, the space between them and the casing decreases on the discharge

side, creating a vacuum on the suction side. This vacuum draws fluid into the

pump. The fluid is then trapped in the spaces between the gear teeth and the

casing and is transported around the casing to the discharge side. As the gears

continue to rotate, the space on the discharge side decreases, which forces the

fluid out of the pump.

·

Internal Gear Pumps: An internal gear pump

consists of two gears: an outer (rotor) gear and an inner (idler) gear. The

rotor gear is driven by the motor, which drives the idler gear. The idler is

mounted on a pivot pin and rotates inside the rotor. As the gears rotate, they

create expanding volume on the inlet side, which draws fluid into the pump. The

fluid is then transported in the spaces between the gear teeth and the casing

to the outlet side. On the outlet side, the gears mesh together, which

decreases the volume and forces the fluid out of the pump.

In both types of pumps, the volume of fluid displaced with

each rotation is very precise, making gear pumps an excellent choice for

metering applications.

Conclusion

Gear pumps stand out in the realm of fluid handling for their remarkable efficiency and reliability, stemming from their simple design, versatility, and self-priming capabilities. The choice between external and internal gear pumps depends on the specific requirements of the application, with external gear pumps excelling in high-speed tasks and internal gear pumps proving ideal for handling high-viscosity fluids. Selecting the right gear pump demands a thorough understanding of the application's nuances, including fluid properties, flow rates, and pressure requirements. The diversity in gear pump types ensures their applicability across various industries, from handling corrosive chemicals to managing abrasive substances. Whether considering external or internal gear pumps, the meticulous evaluation of specifications and material compatibility, coupled with choosing a reputable manufacturer like Viking Pump from IDEX, ensures the optimal performance and longevity of the gear pump, ultimately enhancing operational efficiency.

Comments

Post a Comment