Viking Pump - The Complete Range of Pumps for Liquid Handling

The significance of dependable and energy-efficient pumps cannot be overemphasised. Fluid transfer, circulation, and management are critical to operational performance in a variety of sectors. Recognising this important necessity, Viking Pump has established itself as a prominent brand known for its remarkable range of pumps that have been precisely built to meet the different demands of liquid handling applications. This blog will take you on an informative voyage around the world of Viking Pump, where we will look at their broad array of pumps, such as cutting-edge internal gear pumps, corrosion-resistant stainless-steel gear pumps, and sturdy cast iron gear pumps.

Through a comprehensive examination of their distinctive features, versatile applications, and inherent advantages, we aim to equip you with invaluable insights to facilitate the selection of the ideal pump that precisely aligns with your unique liquid handling requirements. By delving into the realm of Viking Pump, we unveil a realm of possibilities, empowering businesses to achieve optimal fluid management and drive operational excellence.

Internal Gear Pumps: Efficient and

Versatile

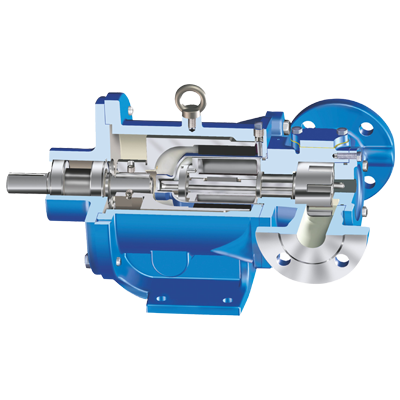

One of Viking Pump's flagship products is the internal gear pump. This type of pump features a unique design that consists of an external rotor and an internal idler gear. The precision meshing of these gears creates a tight seal, enabling the pump to handle various fluids with exceptional efficiency. Internal gear pumps are known for their versatility, making them suitable for a wide range of applications such as chemical processing, food and beverage, pharmaceuticals, and oil and gas. The robust construction and reliable performance of Viking Pump's internal gear pumps make them a popular choice in industries where accuracy and durability are paramount.

Stainless Steel Gear Pumps: Corrosion

Resistance at Its Best

When it comes to handling corrosive fluids and aggressive chemicals, Viking Pump's stainless-steel gear pumps excel in performance and longevity. These pumps are constructed with high-quality stainless-steel materials, providing exceptional resistance to corrosion and chemical attack. Stainless steel gear pumps are widely used in industries such as chemical processing, petrochemicals, pharmaceuticals, and food processing, where maintaining the purity and integrity of the fluids is critical. Viking Pump's stainless-steel gear pumps offer reliability, longevity, and the peace of mind that comes with superior corrosion resistance.

Cast Iron Gear Pumps: Robust and

Durable

For applications that demand durability, strength, and reliability, Viking Pump's cast iron gear pumps are the go-to choice. These pumps are engineered with rugged cast iron construction, making them ideal for handling a wide range of liquids, including viscous fluids, oils, and industrial chemicals. Cast iron gear pumps are widely used in industries such as mining, construction, oil and gas, and general industrial applications. Viking Pump's cast iron gear pumps are designed to withstand demanding conditions and provide long-lasting performance, ensuring uninterrupted liquid handling operations.

Advantages of Viking Pump's Gear Pumps

Viking

Pump's gear pumps offer several advantages that set them apart from the

competition. Some of the key benefits include:

- Precise

and Consistent Flow Control:

The gear design of Viking Pump's pumps ensures accurate and reliable flow

control, allowing for precise dosing and transfer of fluids.

- High

Efficiency: The

internal clearances and close tolerances of the gear pumps result in

minimal fluid slippage and improved overall efficiency, reducing energy

consumption and operational costs.

- Wide

Range of Materials:

Viking Pump offers a variety of materials for pump construction, including

cast iron, stainless steel, and other alloys, ensuring compatibility with

different liquids and environments.

- Robust and Reliable: Viking Pump's gear pumps are built to withstand demanding conditions and provide reliable performance, minimising downtime and maintenance requirements.

Conclusion

Viking Pump has solidified its position as a trusted and renowned brand synonymous with excellence. Their commitment to delivering exceptional pumps tailored to diverse requirements has earned them the trust and loyalty of industries worldwide. Whether it's the unparalleled precision of their internal gear pumps, the corrosion-resistant capabilities of their stainless-steel gear pumps, or the durability and cost-effectiveness of their cast iron gear pumps, Viking Pump offers a comprehensive range of solutions for various applications.

By choosing Viking Pump, businesses gain access to cutting-edge pump technology that ensures reliable and efficient liquid handling. The brand's unwavering dedication to quality, innovation, and customer satisfaction sets them apart as an industry leader. Their pumps are meticulously engineered to deliver exceptional performance, longevity, and peace of mind, enabling businesses to optimise their liquid handling processes and achieve operational excellence.

With a global network of service and support, Viking Pump ensures that customers receive comprehensive assistance throughout the lifecycle of their pumps. From installation and maintenance to troubleshooting and spare parts, Viking Pump's commitment to customer satisfaction is unparalleled.

Hence,

Viking Pump stands tall as a beacon of excellence in the liquid handling

industry. Their complete range of pumps, backed by a legacy of engineering

precision and a passion for innovation, is designed to cater to diverse needs

across industries. By choosing Viking Pump, businesses can elevate their liquid

handling processes, achieving efficiency, reliability, and peace of mind. Trust

Viking Pump and experience the pinnacle of pump technology for your liquid

handling needs.

Comments

Post a Comment