CORKEN Compressor, a Complete Guide

|

| CORKEN Compressor, a Complete Guide |

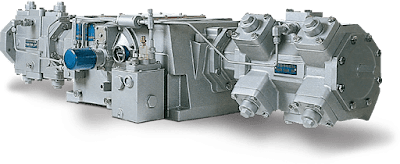

CORKEN compressors stand out as a premier choice in industrial applications for several compelling reasons. Here’s a list that gives us a closer look at each of these factors:

Wide Range of Applications: CORKEN Compressors are engineered for the efficient transfer of a diverse array of industrial gases, encompassing butadiene, hydrogen, helium, methyl chloride, sulfur dioxide, chlorine, refrigerant gases, exotic research gases, corrosive biogases found in landfills, and hydrocarbon gases prevalent in the oil and gas industry. They are used in many applications, including vapour recovery, gas gathering, liquid transfer, instrumentation, pressure boosting, tank car unloading, gas blanketing, PSA gas generation evacuation, and refrigerant reclamation.

Solutions for LPG and Petrochemicals: CORKEN offers a wide variety of industrial compressor solutions for the Liquefied Petroleum Gases (LPG) and other petrochemical industries. The applications of CORKEN compressors extend to various industrial scenarios, including unloading road tankers and rail wagons, deploying mobile-mounted units in emergency rescue vehicles for gas recovery, facilitating cylinder evacuation, and supporting process gas boosters.

High Quality and Innovation: CORKEN's exceptional reputation is built upon nearly 100 years of maintaining the highest quality products and customer service standards. This, combined with their strong commitment to technological innovation, has positioned CORKEN as a global leader in compression and pumping solutions.

Custom Engineered Packages: If the standard compressor mountings do not meet the requirements of the application, CORKEN can supply custom engineered packages.

Leakage Control: CORKEN offers a variety of piston rod packing configurations, distance piece options, and special coatings suitable for a wide range of industrial gases. A double-packed (D-Style) reciprocating compressor offers a moderate level of leakage containment, while a triple-packed (T-Style) compressor offers the highest level of leakage control.

The unloading mechanism of a CORKEN compressor contributes to operational efficiency in several ways. These features make the unloading compressor of CORKEN a key contributor to operational efficiency in industrial applications.

Efficient Transfer of LPG: CORKEN compressors are used for the unloading and efficient transfer of Liquefied Petroleum Gas (LPG). They assure zero leakage and spills, maintaining the required pressure and rate of flow. This ensures that the LPG transfer process adheres to the safety protocols laid out by individual manufacturing plants.

Versatile Applications: The unloadingcompressor is a part of the reciprocating compressor, which is the perfect solution for transferring liquids to and from tanks (tanker unloading compressors) as well as vapor recovery.

High-Efficiency Valves: CORKEN compressors are equipped with high-efficiency valves that ensure quiet and reliable operation.

Reversible Oil Pump: The reversible oil pump allows operation in either direction, adding to the versatility and efficiency of the compressor.

Simplified Top-Down Design: The simplified top-down design of CORKEN compressors means that routine maintenance is minimally invasive, contributing to long-term operational efficiency.

Self-Lubricating Piston Rings: The self-lubricating piston rings minimize oil in gas, reducing the need for regular maintenance and increasing operational efficiency.

Exploring the Versatility of the CORKEN LPG Compressor:

Applications and Benefits:

The CORKEN LPG Compressor is a versatile piece of equipment with a wide range of applications and benefits. It is ideal for transfer equipment where poor NPSH conditions exist. It can be used for non-toxic, non-corrosive applications where oil-free gas and leakage containment are not critical. The compressor is also equipped with a reversible oil pump that allows operation in either direction, adding to its versatility.

CORKEN – The Complete Guide from Purchase to Care

Here's a comprehensive guide on buying a CORKEN compressor from IDEX, its installation, and care:

Buying a CORKEN Compressor from IDEX: IDEX Corporation offers a range of CORKEN compressors of small horsepower, ranging from 7.5 hp to 75 hp. These are oil-free, single or multistage compressors available in vertical and horizontal designs with double (D-Style) or triple packing (T-Style).

Installation: Once you've purchased your CORKEN compressor, the next step is installation. CORKEN provides detailed installation, operation, and maintenance manuals for their compressors. These manuals provide comprehensive instructions on how to properly install your CORKEN compressor. It's important to note that the installation of CORKEN products must be made only by experienced, trained, and qualified personnel.

Care and Maintenance: Regular inspection and maintenance of your CORKEN compressor is essential. This includes periodic checks of the compressor's components as well as routine cleaning and lubrication. CORKEN's IOM manuals provide detailed instructions on how to properly care for and maintain your compressor. Remember, maintenance, use, and installation of CORKEN products must comply with CORKEN instructions, applicable laws, and safety standards.

Conclusion

CORKEN compressors from IDEX Corporation have established themselves as a leading choice in industrial applications, offering a versatile range of solutions for the transfer of various industrial gases. With a century-long commitment to quality and innovation, CORKEN has become a global leader in compression and pumping solutions, particularly renowned for their efficiency and reliability in handling liquefied petroleum gases (LPG) and other petrochemicals. The unloading mechanisms of CORKEN compressors contribute significantly to operational efficiency, ensuring safe and efficient transfer processes. The versatility of their applications, from vapor recovery to gas gathering and tank car unloading, underscores the broad spectrum of industries that benefit from CORKEN's compressors. With a commitment to quality, innovation, and comprehensive customer support, CORKEN stands as a trusted solution provider in the realm of industrial compression technology, meeting the diverse needs of the chemical, petrochemical, and gas processing industries.

Comments

Post a Comment